- +919600067394

- support@peasautomation.com

Domain

Industries We Serve

Automotive & Tyre

Food & Beverages

Infrastructure Projects

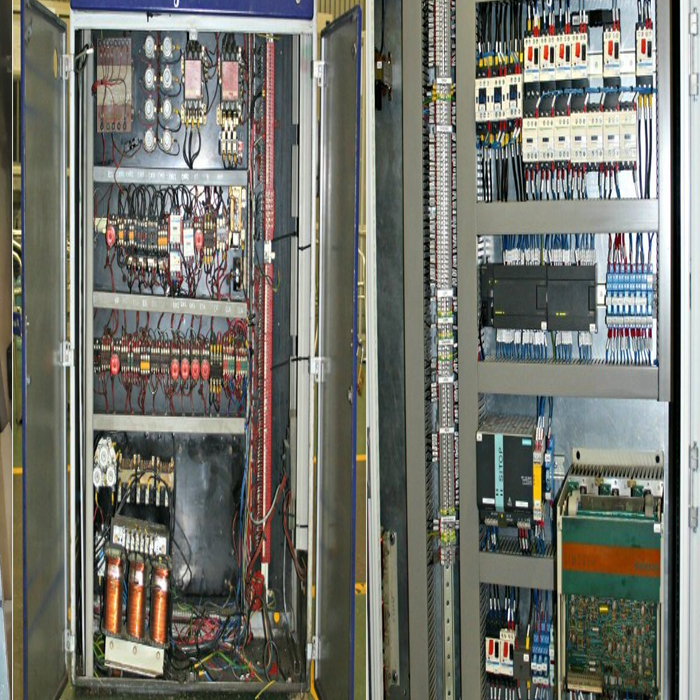

Industrial Automation Solutions

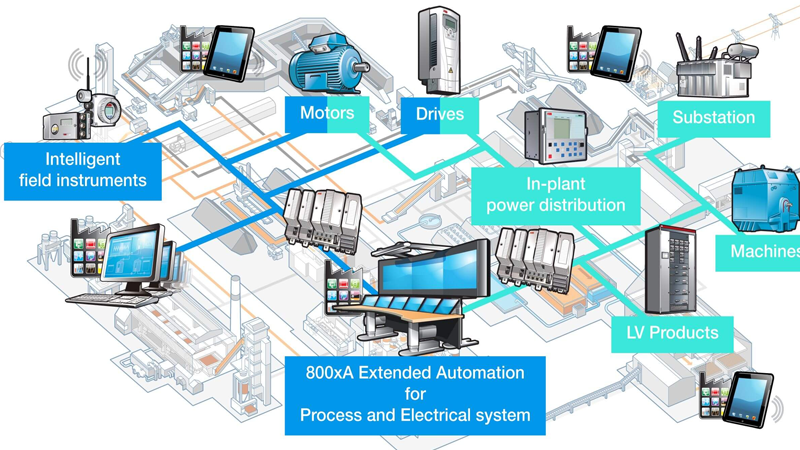

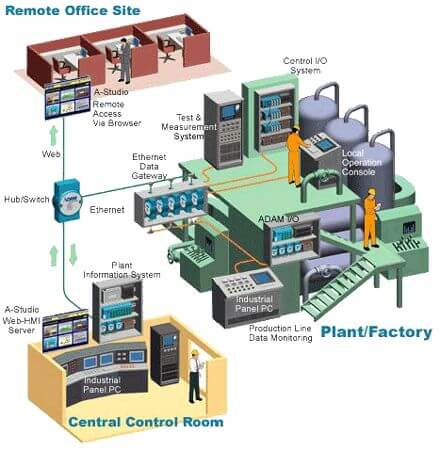

We deliver industrial automation and control through our control systems, motor control, and smart devices portfolios. The combination of these three platforms are architected and designed to help you build the most efficient industrial automation system to meet your needs.

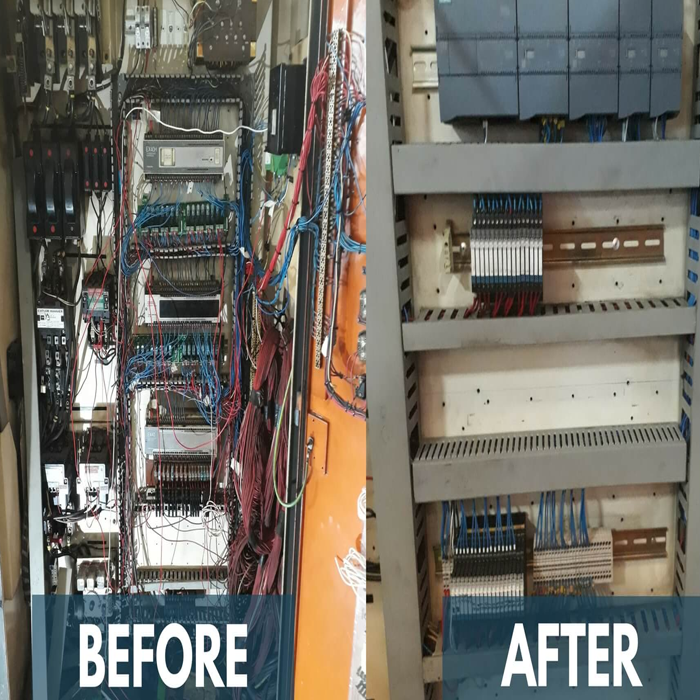

By replacing multiple, disparate control systems with one common framework, it enables efficient installation, operation, and maintenance

If your manufacturing plant / project needs to implement planned automation systems like Programming Logic Controller (PLC), Supervisory Control and Data Acquisition (SCADA) and Distributed Control Systems (DCS).

Our expert services cover engineering, supply, installation and testing/ commissioning of automation systems. We not only specialize in making inclusive automation plans according to the technical requirements of our clients, but also in implementing these plans in an effective manner so as to improve the overall manufacturing process control.

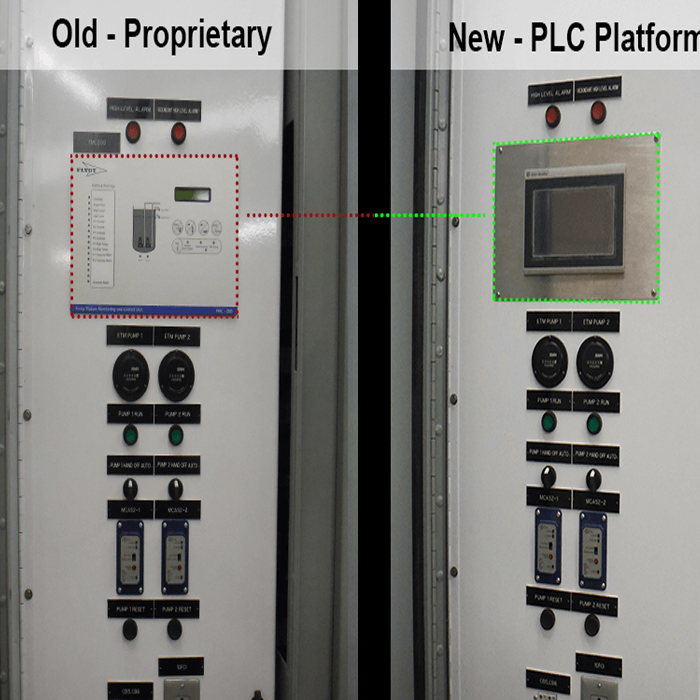

With years of industry experience and superior skills, experts at PEAS have been performing trendsetting PLC/SCADA/DCS Implementation work for quite a few years now. We take special care to understand the technical needs of our clients, as well as their budget requirements, and carry out all planning and implementation work on site, communicating closely with the technical personnel of the company all the time.

We take care of various phases of PLC/SCADA/DCS Implementation such as design, engineering, supply, installation, planning and testing of automation protocols and processes.

A few of our competencies include –

Developing functional design specifications & detailed design specifications inherent to PLC/SCADA/DCS Implementation and making comprehensive procedure plans.

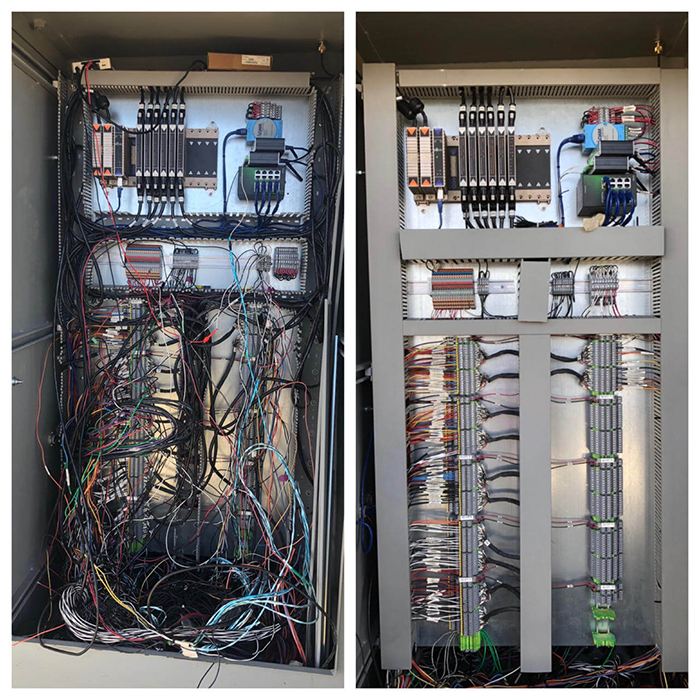

Designing custom control panels including system panels and marshalling panels.

Creating plan diagrams for distribution of power among machines, which includes making a database of the wiring system and its layout.

Making appropriate places for the routing of cables between machines, and setting up junction boxes for intuitive control and operation.

Generation of plan logic from C&I, P&I, FDS and process detail schematics.

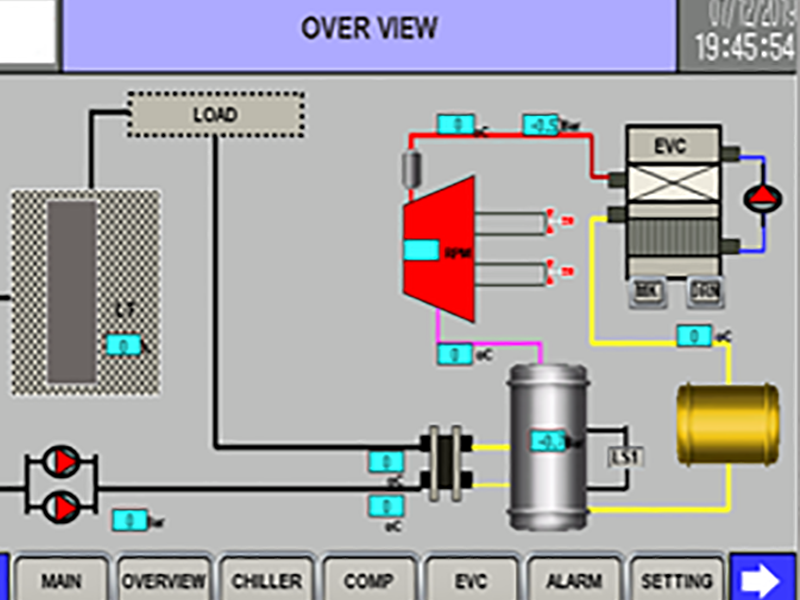

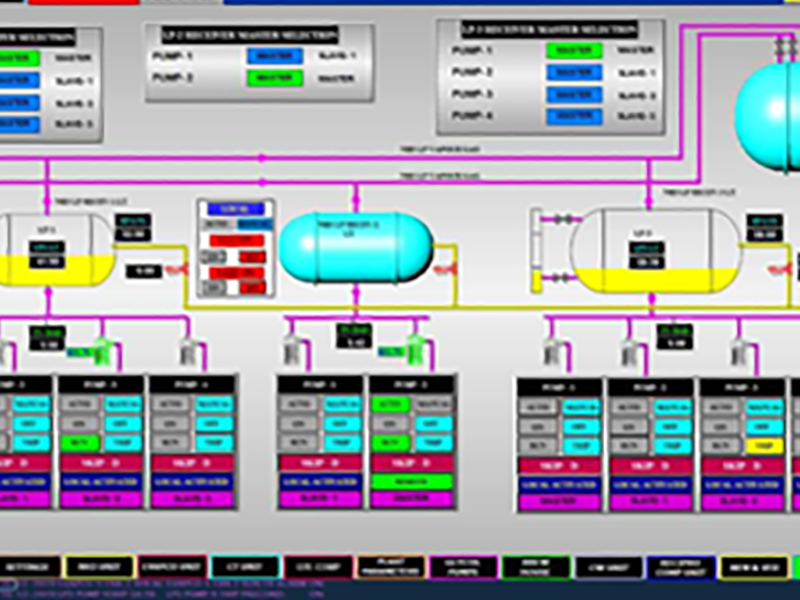

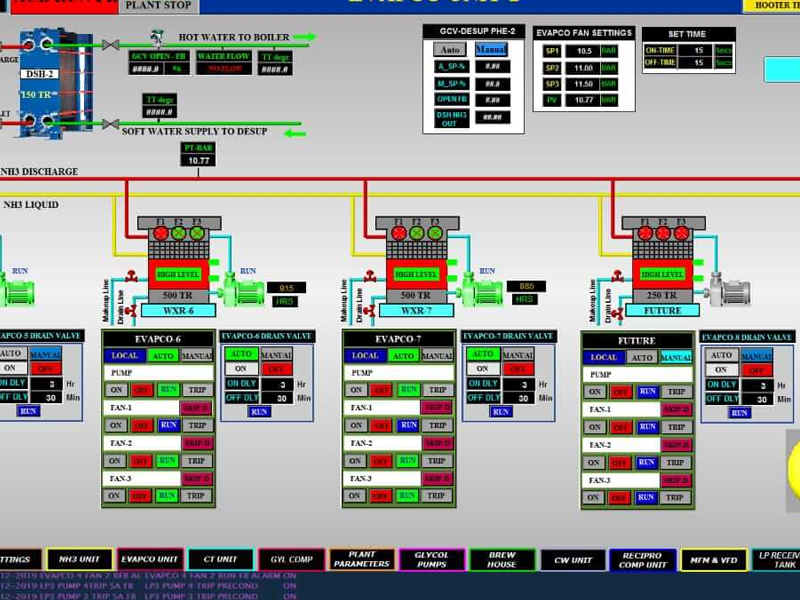

Customized application development and development of SCADA HMI and SCADA graphic content.

Making third party data communication database as well as implementation.

Detailed instrument loop system diagrams and diagrams for interconnection.